By Rohan P Vyas, Huliot Pipes and Fittings Pvt. Ltd.

ClearBlackTM is a modular wastewater treatment plant designed and developed by the Huliot Advanced Flow Systems for treatment as well as reclamation and reuse of treated sewage for non-potable purposes.

The system presents the Sewage Recycling and Reuse as the best symbiotic solution complementing the optimization of freshwater resources in the time of ongoing water stress and saving them by getting polluted simultaneously by its untreated discharge into the river bodies.

The development of the system draws its inspiration from Israel’s Wastewater Management Policy where about 500 Million cubic meter of sewage is produced in Israel every year and 93% of it is treated and reclaimed for reuse reducing the freshwater demand for agriculture by 25-30%.

The system is designed REAL SMART to operate on its own automatically with Israeli Technology including a Real Time Monitoring System displaying the plant performance on a Smartphone Screen. A Screenshot has been shared from one of the trial runs has been depicted below

- TECHNOLOGY

The system uses the most advanced and efficient technology of MBR combining activated sludge process treatment with submerged membrane filtration. The membranes with a pore size of0.04 micron separating all the solids in the process, giving away the solids free clear water. This system is the most compact one among all other systems eliminating the secondary treatment of clarification and tertiary treatment of Pressure Sand Filtration and Activated Carbon Filtration.

The system is tolerant to organic and hydraulic fluctuations producing steady high quality with minimal technician attendance and automated cleaning arrangements.

The treatment process strictly adheres the revised norms of treated sewage discharge as per notification of National Green Tribunal of India (NGT) dated 30th April 2019. The system produces an excellent output water quality consistently with following parameters:

A picture of the treated water quality from trial run of 100 KLD in India has been depicted below:

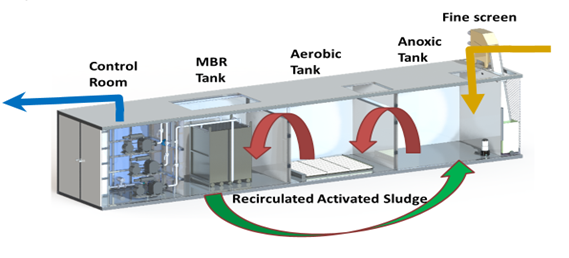

- WORKING PRINCIPLE & TREATMENT SCHEME

ClearBlackTM works on the principle of biological treatment of sewage based on the well-known activated sludge process and combines a remarkable ultrafiltration membrane system to consistently produce a colour free, odour free and disinfected treated water safe to handle and reuse.

The treatment scheme for the system is described below:

- The raw sewage first requires pre-treatment for separation of large solids and Oil & Grease.

- The pre-treated raw sewage undergoes homogenization in a collection tank and is pumped to the ClearblackTMSystem. The pre-treated sewage is further screened through an automatic rotary drum screen to separate all the particles larger than 2 mm.

- The screened sewage enters the Anoxic tank for decomposition of nitrogen compounds which contribute to its pollution. The tank is provided with a mixing arrangement for incoming sewage flow and RAS (Return Activated Sludge) flow.

- It further undergoes Aerobic treatment in aeration tank for decomposition of compounds of carbon i.e. BOD and COD, which again contribute to its pollution. The tank is installed with a fine bubble diffuser system supplied with air from the blowers.

- Lastly it enters the MBR tank installed with the membrane system producing exceptionally clean and filtered water. The system is equipped with an automatic cleaning arrangement for membranes. The RAS is recirculated back to the anoxic tank.

A Conceptual Sketch for the treatment scheme inside the ClearblackTMSystem is depicted below:

- APPLICATIONS OF CLEARBLACKTM OUTPUT WATER:ClearBlackTM alters the water management approach from ‘use and throw’ to a ‘use, treat, and reuse’ approach for saving the most vital resource on earth by making the treated water available for the following major uses:

i. Flushing:Flushing is usually the biggest water hog and accounts for 35-40 % of water demand. ClearBlackTMwill treat the flushed wastewater and recycle it back for flushing again.

ii. Vehicle & Floor Washings:A significant amount of water is consumed in keeping the external floorings clean & hygienic as well as vehicle washings etc. at intervals. ClearBlackTM treats the water wasted in such activities and recycle it for reuse again saving all the water while helping in staying clean and hygienic.

iii. Industrial Processes:The treated water from ClearBlackTMcan significantly supplement the freshwater demand in industrial processes and utilities such as Cooling Tower Make-up, Boiler Blowdown Make-up, and Preparation of chemical solutions for ETPs etc.

iv. Gardening:ClearBlackTM is perfectly fit to use for maintaining the greenery for any kind of area including public parks, sports fields, and tracks etc.

v. Ground Water Recharge:ClearBlackTM is absolute solution to recharge ground water to maintain humidity levels in soil.

- SLUDGE MANAGEMENT: The sludge management in ClearBlackTMSystem is made simpler comparative to the existing complex systems in following ways:

• The sludge generated in the system is minimal – almost 1/3rd of the conventional systems.

• The sludge wasting can be carried out in long intervals of 30-60 days.

• There is an option of an additional fully automatic multidisc press for sludge dewatering.

• The dewatering press is provided with the self-cleansing mechanism and requires no manual intervention.

• The power consumption of the dewatering press is incredibly low, between 0.2-0.5 kW only with noise levels less than 65 dB.

• The dried sludge can be disposed/processed/reused in lawns as per the local authority norms.

- SALIENT FEATURES OFCLEARBLACKTM SYSTEM: ClearBlackTM is a simple, smart, and reliable solution for sewage treatment, recycling and reuse with following features:

i. 100 % Sewage Recovery

ii. On-Site Treatment, Recycle and Reuse of Available Wastewater for several Non-Potable Purposes

iii. Optimization of Freshwater Resources to Save It for Future Generations

iv. Completely Automated Process Operation with IoT & Smartphone Connectivity

v. No Tertiary Treatment Required

vi. Compact & Modular Design

vii. Lower Space Requirement

viii. Lower Power Requirement

ix. Lower Chemical Consumption

x. Easy Sludge Management

- ADVANTAGES & BENEFITS OF CLEARBLACKTM SYSTEM:

i. Return on STP Investment is less than 5 Years.

ii. Odour free, Colour free& Disinfected Output Water Safe to Handle & Reuse.

iii. Occupies 50-60% Less Space than Conventional Systems.

iv. Lower Operation Costs due to Lower Power Consumption.

v. The Existing STPs can also be upgraded withClearBlackTM System.

vi. Significant Savings achieved on Energy and Life Cycle Costs.

vii. Can be installed in Remote Areas Having No Sewerage Networks upto Centralized STPs.

viii. Off-Site Operations and Real Time Monitoring for less accessible and remote areas with Online Access.

ix. Process Operation does not require 24 x 7 Skilled Operators.

- DISTINCT ADVANTAGES IN PANDEMIC SITUATIONS LIKE COVID-19:

i. The sophisticated automation with Israeli Technology allows the system to operate on its own without the requirement of personnel for strict supervision.

ii. The operations monitoring can be carried out online on the Smartphone without the need to daily visit the site.

iii. The Ultrafiltration Membrane System is helpful in restricting most of the bacteria and many viruses in the treated water.

A Brief Case Study:

Huliot India has recently pursued one farm house owner who has a farm house in area of 2.5 acre. There is huge garden area also with swimming pool facility. Total occupancy in the farm house is more than 25 persons considering owner and his family, workers to take care of the surroundings. Huliot India has recommended to install smallest STP of 3 KLD capacity by which gardening, flushing and other requirements like road washing and car washing can be done. Owner agreed to install the plant and we have installed the plant for which actual pictures are as below:

This STP has a very low foot print say 10 ft. X 6 ft. STP has been installed and it is completely working fine. Also the STP is fully automatic with timer based PLC controller based panel. Hence, there is no requirement of 24X7 manpower for operation of the STP. It is running satisfactorily in automation with no continuous supervision.